Engine Dyno Testing/Tuning

Engine Dyno testing a modified performance engine is an absolute must. Any time someone changes, adds or modifies the design of a component of an engine other than friction parts, the engine requires a new tune up, even if you've already had one previously. Factory tune-ups are for factory built engines, not modified engines. Even the simplest example would be if you changed the air filter assembly to a larger or smaller design, the engine will now require recalibrating the air/fuel ratio. Changing the cylinder heads, intake and a camshaft will require a huge change in the engines tune up. At RCS we have dyno tested thousands of engines over the years and again we are looking into a third dyno replacement. That goes to show the importance, how we and our customers feel in having a properly tuned and tested engine. The best track tuners have been shocked when they finally have their engines tested, only to return to the track faster than they were before.

Testing an engine prior to installation can reveal a lot of issues before hand, once the engine is in the car, that's the last place you want to find that problems exist. Testing on the dyno can confirm that the engines tune up is correct and the power level is where is should be. Testing reveals the engines durability and gives us a chance to check everything about the engine possible, including oil and fuel leaks that can make a nasty mess of things once the engine is installed and running in the car. In addition engine break-in is critical for proper ring seal, and camshaft/lifter break-in if flat tappet. During the break-in period we can monitor ring seal, oil temps, oil pressure, water temps, engine rpms, fuel pressure, and any accessory issue and apply an actual load on the engine as if we were driving it in a car. Another great thing is we can test each accessory part like ignition systems, coil, and ignition wires to make sure there doing there part. We can test ECU communication problems or sensor operating values. A good tuner can dial your engine in and tune it like a jeweled watch.

The amazing part of dyno testing an engine is the amount of data you receive is seconds, or the actual observed data. An actual accelerating test under a load takes an average of 7-8 seconds to go through the preset rpm test. In that amount of time we gather hundreds of bits of information related to how the engine is performing and what it's experiencing. A good tuner will never go to full throttle without knowing they are very close on air fuel ratio and ignition timing, so there's a lot of calculations and measurements that have to be performed prior to testing. Not all dyno operators and tuners are equal, the dyno doesn't make any adjustments to the engine it requires a knowledgeable operator and tuner. All dyno's do is just read and record hard data, that's all.

Imagine being in your car at 6500 rpms in high gear, what do you think it would take to simulate that, you would need a very long straight highway for sure. On a dyno that's what we do, we simulate high speeds in high gear under max load. Without an engine dyno, engine builders had to take their cars to the track for serious tuning, I don't care who you are, tuning at a track takes at least 3 passes to create averaged amount of information, and another three passes for the next comparison to be able to tune remotely accurate, and well never be as good as a dyno can measure. Tuning at the track can create a whole list of other problems that you might run into, not to mention the cost and time. Now if you were a weekend racer that would be different because you’re there racing and tuning the car for competition every weekend and prepared for the cost and time it takes, which is a by-product of racing. Not everyone wants to go to the track, especially every weekend unless you’re a competitive racer. Most people that aren’t racers just want the engine to perform to its maximum potential and have some documentation for resale reasons and bragging rights.

Below is a EFI system with a RCS 2,400 CFM Throttle Body, This 400 Ford Cleveland 10.8-1 compression engine on pumps gas, produced 730 Hp and 612lbs of torque by 6,500.

Engine Dyno sessions are normally a 10 hour day. A 10 hour day consist of loading the engine on a stand into the dyno cell, along with all the connections required to run the engine, a tuning session and then engine removal. Engines that are more complicated require more time to install them. Dry Sump engines, multiple carburetors, and fuel injection engines normally increase the dyno installation time as well as time in tuning. When doing Research and Development, engines can be on the dyno for weeks at a time performing as many as 100 test, testing parts and engine combinations.

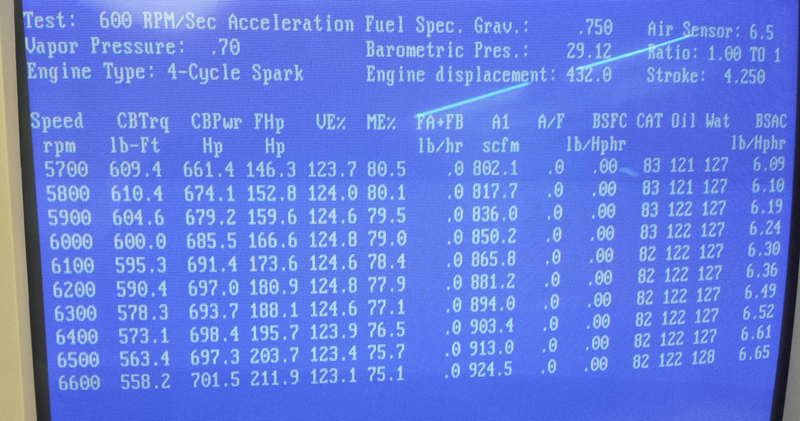

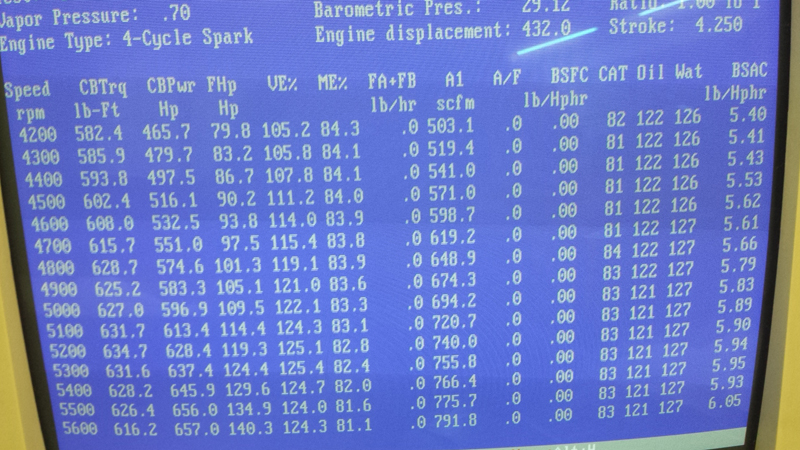

Below is an engine and dyno sheet for a 1050 CFM Carbureted 432 Ford Cleveland 11 to 1 compression engine on pump gas. The engine was assembled with both fuel systems for testing purposes.

432 Carburetor Test

Without an EFI fuel map created, we started the engine and went through normal engine break-in with a carburetor. We knew the engine wasn't going to make its max power with the carburetor. The 1050cfm carburetor really was hurting the engines breathing capabilities only making 701Hp and 635lbs of torque, we later installed the 1,375 cfm EFI throttle body and the engine made 750Hp and 660lbs. after a good tuning session. The ability to predict an engines power level prior to final tuning is what makes the difference in engine builders and tuners. A 49Hp and 25lb of torque increased power gain at peaks by knowing the fuel system changes made would make that much difference.